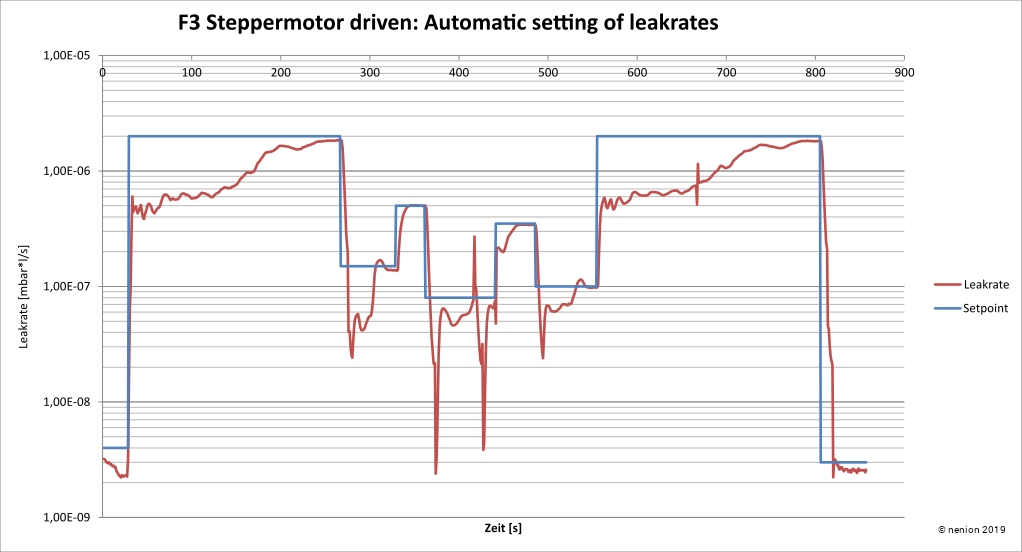

The steppermotor driven valve allows the automation of the gasdosing process. By menas of the steppermotor driven UHV Gasdosing Valve closed loop control of gas flow or pressure in all vacuum areas from low, fine and high to ultrahigh vacuum is possible.

The controller provides different infterfaces:

USB

Ethernet

MODBUS

Analog (M12 connector)

You may also:

Connect a snesor (flow, pressure) to it and control your process as a closed loop.

Control the valve manually via touch input.

The resolution per stroke is very high: 1,000,000 steps.

The valve has an encoder, so ythe process is monitored.

Ther is also a visual indication of the valve position.

A thermal insulation ensures, that you can heat the valve body up to 150°C, while the motor is connected. For higher bake-out temperatures, you have to disconnect the motor.

The products ships with Controler, mains cable, USB-connections cable and 5m Motor cable.

| Technical Specifications | |

|---|---|

| Material Housing | 1.4404 (316L) |

| Material Sealing | 1.4435 (316L) gold plated |

| Material not in contact with gas | 1.4301 (304) |

| Lifetime | 100,000 cycles until first service |

| Mounting Position | any |

| Internal Pressure | Vacuum to 10 bar |

| Inlet Pressure | 10 bar from each side |

| Tightness Housing | 1*10 -10 mbar.l/s |

| Tightness Valve Seat | 1*10 -10 mbar.l/s |

| Volumes: | |

| Main Flange | 1.0 - 1.4 cm 3 |

| Side Flange | 4.6 cm 3 |

| Bakeout Tempertaure: | |

| Valve Open | 450°C |

| Valve Closed or in Operation | 300°C |

| Weight: | |

| CF 16/16 | 3.8 kg |

| CF 35/16 | 4.4 kg |

| VCR 1/4" | 3.7 kg |

| Actuator: | |

| Time to travelk across stroke | 14 seconds |

| Steps / Stroke | 1,000,000 |

| Interfaces | USB Ethernet Modbus Analog |

| Input | Touchscreen |

| Operational Modes | Manual Closed Loop Control Script Commands |

Gas Dosing Properties

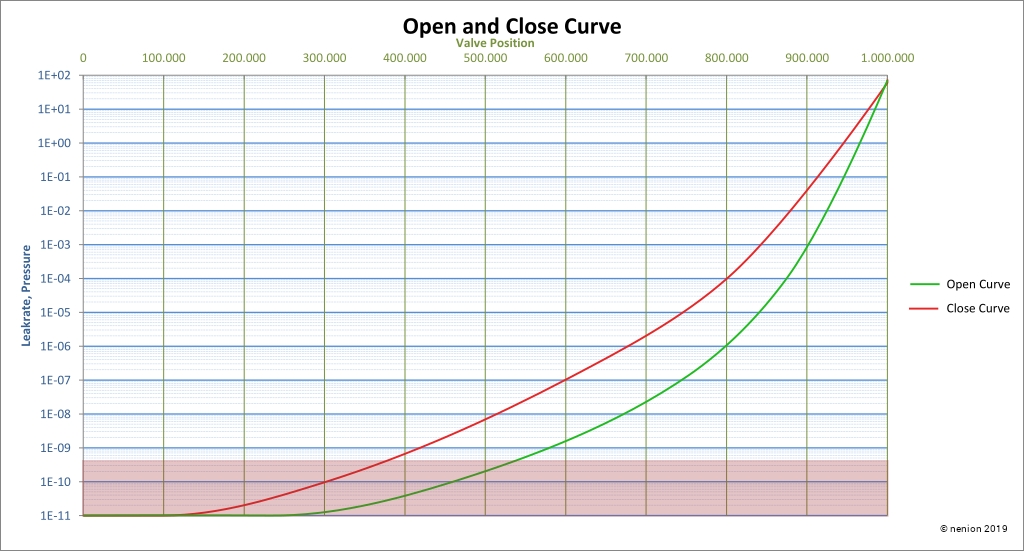

Closing and opening

Idealized measurement protocol: The valve is closed from position 1,000,000 to position 0 and then opened again. The red curve is the closing curve and green is the open curve.

The first 300,000 steps the diaphragm does not touch the valve seat.

When used in room temperature control between 10-9 and 10-10 is not possible due to physical restrictions (red area in diagram). However, it is possible when heating the valve body.

Maximum throughput is60 mbar.l/s.